|

| The Wheat Cleaner 1.0 |

Introducing, the Wheat Cleaner 1.0!

As some may know, we like to grind our own wheat in the Perreault household. Before grinding (or in the case of our flour making machine, impacting), the wheat kernels must be cleaned. Before going on, I know many people call them wheat berries, but for some reason, I just can't latch on to that nomenclature. Moving on...Cleaning really just consists of separating the chaff and dried grasshoppers and beetles that are remaining in the wheat I get from my parents' farm in Minnesota. Now if that last statement grossed you out, get over it. Do you really want to know what is allowed to go into your store-bought processed food? Well, do you? Didn't think so. Besides, I told you the Wheat Cleaner 1.0 is used to remove it, so no harm done. Right? Although I'm sure the bugs would be a good source of protein!

My previous cleaning method was pretty much medieval. I would pour buckets of wheat back and forth in the breeze (or use my own hot air) to remove the undesired particulate. This worked well enough for small batches of wheat. But lately, we've been using much larger quantities (we have a lot of growing boys you know!), and a more time efficient method of cleaning was required.

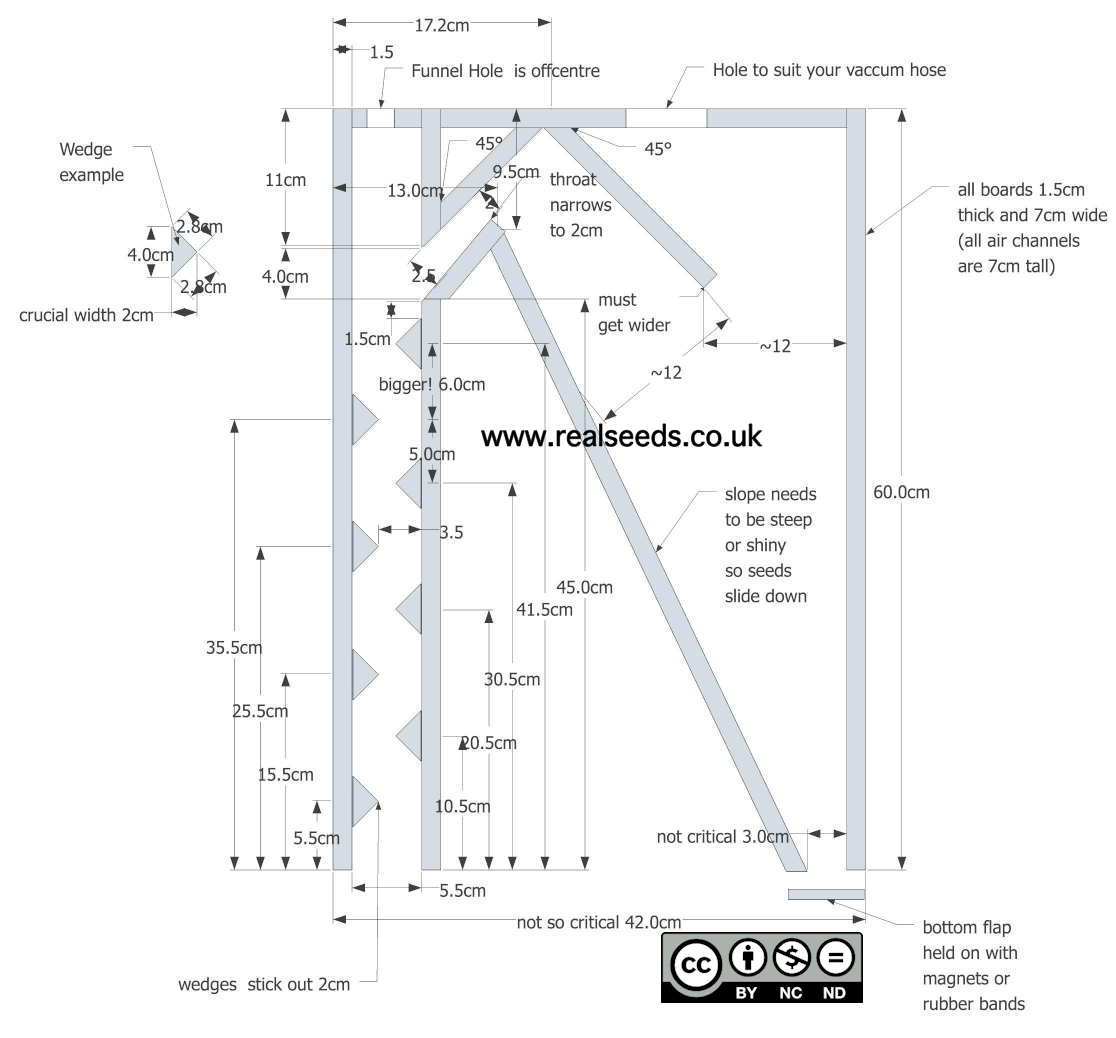

So, hopping on the internet, I searched for solutions. Most grain cleaning solutions were geared towards industrial usage, and not necessarily what I was looking for. They were expensive and bulky, and not suited for my home use task. Then I started finding contraptions that were being used to sort seeds. Both for agricultural purposes, and for bird feeding purposes. I ended up building a unit based on the plans at http://www.realseeds.co.uk/seedcleaner.html. The following is an image of the open source plans they provided.

The unit uses a shop-vac to create an updraft, thereby allowing the heavier wheat kernels to pass through a vertical separation chamber, and the lighter weed seeds and chaff to be sucked out. The vertical separation chamber has a series of flow disrupters, which I'll refer to as 'plinkos'. There is a draft control on the front that allows the amount of updraft to be varied for fine tuning the separation. The current design works well if I control the inflow of raw material. If too much wheat enters the vertical chamber, the suction increases due to the decrease in the chamber cross-sectional area, and most of the wheat gets pulled into the waste collection area. So, one of my improvements is to create some sort of intake flow control.

The completed unit is about 24 inches tall, by 17 inches wide. The depth is about 3 inches. The side walls are made from pieces of melamine covered particle board. I used one 48"x11"x3/4" piece of the this material for the entire unit, which cost me $2.29 at Menard's. For the top and bottom, I used 1/4 inch hardboard, which I picked out of a dumpster at a construction site. And the clear plastic covering the separation chamber was laying around my house. So, so far, the total material cost has been $2.29 plus the cost for some screws.

No comments:

Post a Comment